Melt blown fabric machine is a specialized equipment used to produce melt blown nonwoven fabric, which is a key material used in the manufacturing of various medical, hygiene, and filtration products.

Melt blown nonwoven fabric is made by melting and extruding polymer resins such as polypropylene through a spinneret with many small nozzles. The molten polymer is then blown by hot air or other gas to form ultra-fine fibers with diameters ranging from a few microns to tens of microns. These fibers are collected onto a conveyor belt or drum to form a web, which is then bonded by heat, pressure, or chemicals to create a strong and uniform fabric.

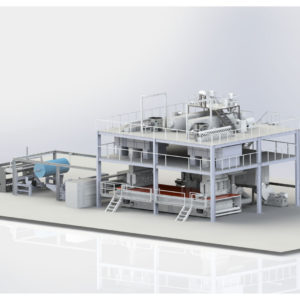

Melt blown fabric machines typically consist of a feeding system for the polymer resin, a heating and extruding system for melting the resin and extruding it through the spinneret, a high-velocity hot air or other gas system for blowing and stretching the fibers, and a collection system for the fabric.

The melt blown nonwoven fabric produced by these machines has excellent filtration properties, high absorbency, and good barrier performance, making it an essential material in the production of medical face masks, surgical gowns, disinfectant wipes, air and water filtration systems, and other hygiene and safety products.

The Advantages And Disadvantages Of melt blown fabric machine

- High efficiency: Melt blown fabric machine can produce high-quality melt blown nonwoven fabric with high efficiency and stable performance.

- Versatility: Melt blown nonwoven fabric can be customized to meet specific needs of different industries and applications, including medical, hygiene, filtration, and insulation.

- Cost-effective: Melt blown nonwoven fabric is a cost-effective material due to its low weight, high filtration efficiency, and ability to be produced in large quantities.

- High filtration efficiency: Melt blown nonwoven fabric has excellent filtration properties, making it ideal for use in medical face masks, surgical gowns, and air and water filtration systems.

- Lightweight and breathable: Melt blown nonwoven fabric is lightweight, breathable, and comfortable to wear, making it an ideal material for use in medical and hygiene products.

Disadvantages of melt blown fabric machine:

- High initial investment: Melt blown fabric machines are expensive and require significant capital investment.

- Complex technology: Melt blown fabric machines require skilled technicians and operators who are familiar with the complex technology and processes involved in the production of melt blown nonwoven fabric.

- High energy consumption: Melt blown fabric machines require a lot of energy to operate, which can increase production costs and have an environmental impact.

- Limited raw material options: Melt blown nonwoven fabric is typically produced using polypropylene resin, which limits the range of raw material options available.

- Susceptible to damage: Melt blown nonwoven fabric is fragile and can be easily damaged if not handled carefully during the production process.