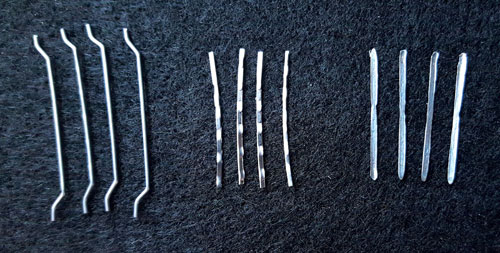

Hooked end steel fiber is a type of fiber that is produced through a process called hooking, which involves attaching a hooked end to the fiber. This process creates a fiber with a unique structure that is characterized by a hooked end and a straight or curved section.

Hooked end steel fiber is commonly used in various applications, including textiles, composites, and advanced materials. It is known for its high strength, stiffness, and resistance to fatigue, making it an ideal material for a wide range of industries.

Properties of Hooked End Steel Fiber

Hooked end steel fiber has several unique properties that make it an attractive material for various applications. Some of these properties include:

- High strength: Hooked end steel fiber has a high tensile strength, which makes it suitable for applications that require high strength.

- Good stiffness: The hooked end structure of hooked end steel fiber results in good stiffness, which makes it suitable for applications that require high stiffness.

- Fatigue resistance: Hooked end steel fiber has a high fatigue resistance, which makes it suitable for applications that require high fatigue resistance.

- Low weight: Hooked end steel fiber has a lower weight than other types of fibers, which makes it suitable for applications that require lightweight materials.

Applications of Hooked End Steel Fiber

Hooked end steel fiber is used in a wide range of applications, including:

- Textiles: Hooked end steel fiber is used in the production of textiles, such as clothing, upholstery, and carpets.

- Composites: Hooked end steel fiber is used in the production of composites, which are materials composed of two or more materials.

- Advanced materials: Hooked end steel fiber is used in the production of advanced materials, such as those used in the aerospace and automotive industries.

Manufacturing Process of Hooked End Steel Fiber

The manufacturing process of hooked end steel fiber involves several steps, including:

- Production of raw materials: The first step in the manufacturing process is the production of raw materials, such as steel and carbon fibers.

- Mixing of raw materials: The raw materials are mixed to form a composite material.

- Drawing of fibers: The composite material is then drawn into fibers using a drawing machine.

- Hooking of fibers: The fibers are then hooked using a hooking machine, which attaches a hooked end to the fiber.

- Testing of fibers: The hooked end steel fibers are then tested for their properties, such as strength, stiffness, and resistance to fatigue.

Conclusion

Hooked end steel fiber is a versatile material that is used in a wide range of applications, including textiles, composites, and advanced materials. Its unique properties, such as high strength, good stiffness, and fatigue resistance, make it an ideal material for various industries. The manufacturing process of hooked end steel fiber involves several steps, including the production of raw materials, mixing of raw materials, drawing of fibers, hooking of fibers, and testing of fibers. Overall, hooked end steel fiber is a valuable material that is used in many different industries.