Steel fiber, a versatile material, has numerous applications across various industries. Its unique properties make it an ideal choice for a wide range of uses, from construction to automotive. In this article, we will explore the various aspects of steel fiber and its benefits.

Applications of Steel Fiber

Steel fiber is widely used in the construction industry for its high strength-to-weight ratio and durability. It is used in concrete as a reinforcing material, providing improved mechanical properties and reducing the risk of cracking.

Steel fiber-reinforced concrete is also used in the construction of bridges, high-rise buildings, and other structures. Additionally, steel fiber is used in the production of fiber-reinforced polymer (FRP) composites, which are used in various applications, including aerospace, automotive, and marine industries.

Advantages of Steel Fiber

The advantages of steel fiber are numerous, making it a popular choice for various applications. Some of the key benefits include:

- High strength-to-weight ratio: Steel fiber has a high strength-to-weight ratio, making it an ideal choice for applications where weight is a critical factor.

- Durability: Steel fiber is highly durable and resistant to corrosion, making it suitable for use in harsh environments.

- Flexibility: Steel fiber can be easily shaped and molded into various forms, making it a versatile material for different applications.

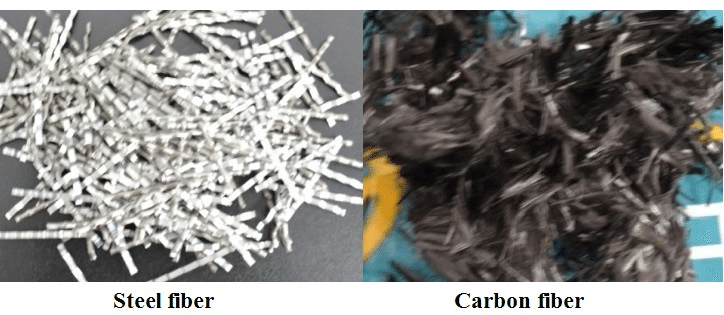

- Cost-effectiveness: Steel fiber is a cost-effective material compared to other reinforcing materials, such as carbon fiber.

Production Process of Steel Fiber

The production process of steel fiber involves several stages, including:

- Material selection: High-quality steel is selected for the production of steel fiber.

- Melting: The steel is melted in a furnace to form a molten metal.

- Extrusion: The molten metal is passed through a die to form a long, thin strand.

- Cooling: The strand is cooled and solidified, resulting in a steel fiber.

Types of Steel Fiber

There are several types of steel fiber, including:

- Deformed steel fiber: This type of steel fiber has a deformed shape, which provides better grip and bonding with the concrete.

- Smooth steel fiber: This type of steel fiber has a smooth surface and is used in applications where high ductility is required.

- Crimped steel fiber: This type of steel fiber has a crimped surface and is used in applications where high tensile strength is required.

Examples of Steel Fiber Applications

Steel fiber has numerous applications across various industries, including:

- Construction: Steel fiber-reinforced concrete is used in the construction of bridges, high-rise buildings, and other structures.

- Automotive: Steel fiber is used in the production of automotive parts, such as brake pads and clutch disks.

- Aerospace: Steel fiber is used in the production of aerospace components, such as aircraft structures and engine parts.

- Marine: Steel fiber is used in the production of marine components, such as boat hulls and propellers.

In conclusion, steel fiber is a versatile material with numerous applications across various industries. Its high strength-to-weight ratio, durability, flexibility, and cost-effectiveness make it an ideal choice for various applications.

The production process of steel fiber involves several stages, including material selection, melting, extrusion, and cooling. There are several types of steel fiber, including deformed, smooth, and crimped steel fiber. Steel fiber has numerous applications in the construction, automotive, aerospace, and marine industries.