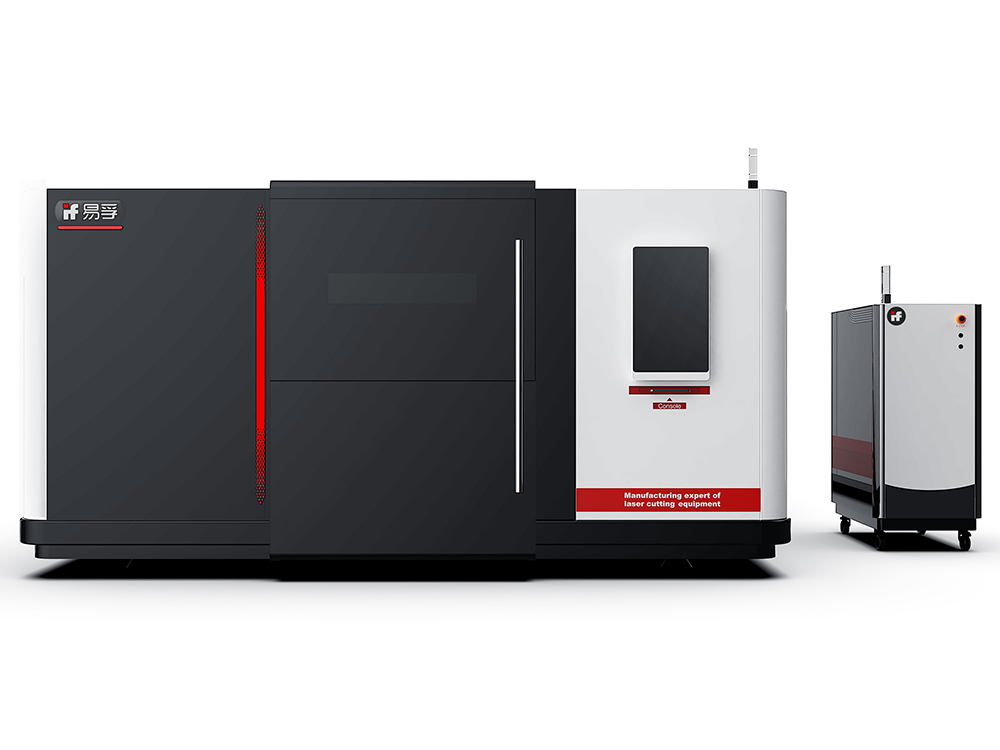

Regular checks and maintenance of a Metal Sheet Laser Cutting Machine’s laser beam delivery system, including components like beam switches, beam expanders, and beam combiners, are crucial for ensuring optimal performance and longevity of the equipment.

Here are some guidelines for conducting these checks:

- Visual Inspection: Conduct regular visual inspections of the laser beam delivery system components to check for any signs of damage, wear, or contamination. Look for cracks, scratches, or other physical damage on the surfaces of beam switches, expanders, and combiners.

- Cleanliness: Keep the beam delivery system components clean and free from dirt, dust, or debris that could affect laser beam quality and performance. Use a clean, lint-free cloth or specialized cleaning wipes to gently wipe the surfaces of beam switches, expanders, and combiners.

- Alignment Check: Periodically check the alignment of beam switches, expanders, and combiners to ensure that they are properly aligned along the optical path. Use precision alignment tools, such as laser alignment systems or alignment lasers, to verify alignment and make adjustments as needed.

- Beam Quality Analysis: Use beam profiling tools, such as beam analyzers or beam profilers, to analyze the quality of the laser beam after it passes through the beam delivery system. This allows operators to identify any aberrations or irregularities in the beam profile and make adjustments as needed to improve cutting performance.

- Mechanical Inspection: Inspect the mechanical components of the beam delivery system, Metal Sheet Laser Cutting Machine such as mounting brackets, hinges, and fasteners, to ensure that they are secure and functioning properly. Tighten any loose fasteners or replace damaged components as necessary.

- Optical Component Inspection: Check the condition of optical components, such as lenses, mirrors, and beam expanders, within the beam delivery system. Look for signs of contamination, degradation, or damage, and replace any worn or damaged components to maintain optimal laser beam quality.

- Calibration: Perform periodic calibration of the beam delivery system components to ensure that they are operating within specified tolerances. Follow the manufacturer’s recommendations for calibration procedures and frequency to maintain optimal cutting performance.

- Documentation: Keep detailed records of checks, maintenance, and calibration procedures for the beam delivery system components. This documentation helps ensure consistency and traceability in the maintenance and performance of the laser cutting machine.

By following these guidelines and implementing a proactive maintenance program for the laser beam delivery system, operators can ensure that the Metal Sheet Laser Cutting Machine operates at peak performance and produces high-quality cut parts consistently.