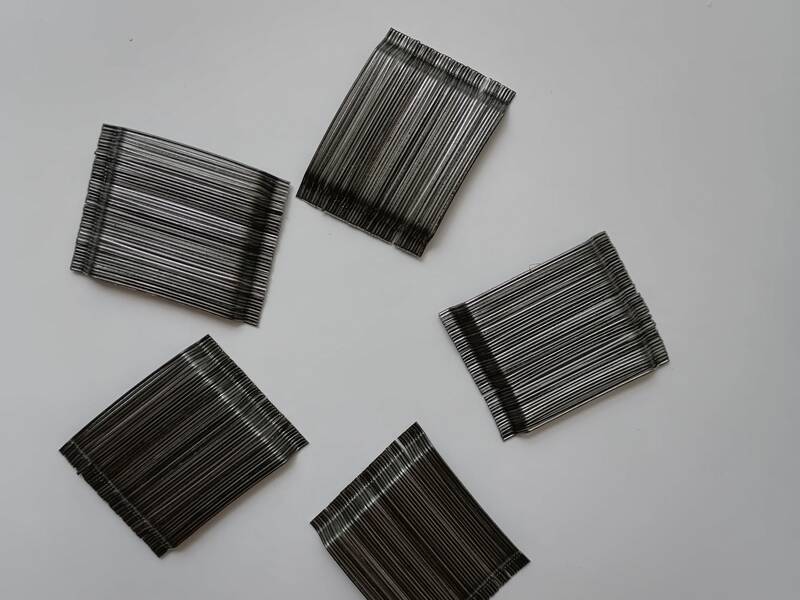

Discover the advantages of incorporating loose hooked end steel fiber in concrete structures. As a trusted solution for reinforcement, loose hooked end steel fiber enhances the durability, strength, and crack resistance of concrete. In this article, we will explore the benefits of using loose hooked end steel fiber, its applications in construction, and how it improves the performance of concrete structures. Whether it’s for industrial flooring, precast elements, or shotcrete applications, loose hooked end steel fiber provides superior reinforcement, reducing the need for traditional reinforcement methods and ensuring long-lasting, reliable structures.

Introduction: Strengthening Concrete with Loose Hooked End Steel Fiber

Advantages of Loose Hooked End Steel Fiber

Using loose hooked end steel fiber in concrete offers several key advantages:

- Enhanced Crack Resistance:

Loose hooked end steel fiber improves the crack resistance of concrete structures. The fibers provide additional reinforcement throughout the entire matrix, reducing the propagation of cracks and minimizing their width. This results in more durable and long-lasting concrete, capable of withstanding heavy loads and environmental stresses. - Increased Flexural and Impact Strength:

The incorporation of loose hooked end steel fiber significantly enhances the flexural and impact strength of concrete. The fibers act as reinforcement, distributing stresses more evenly and improving the overall structural integrity. This makes the concrete more resistant to bending, impact forces, and dynamic loads. - Improved Durability:

By reinforcing the concrete matrix, loose hooked end steel fiber improves its durability. The fibers provide resistance against abrasion, shrinkage, and temperature variations, reducing the risk of premature deterioration. This ensures that the concrete structures maintain their strength and performance over an extended period.

Applications of Loose Hooked End Steel Fiber in Construction

- Industrial Flooring:

Loose hooked end steel fiber is commonly used in industrial flooring applications. It provides enhanced load-bearing capacity and crack control, making it suitable for warehouses, distribution centers, and manufacturing facilities. The fibers improve the overall durability of the concrete floor, reducing maintenance requirements and extending its service life. - Precast Elements:

Loose hooked end steel fiber reinforcement is widely employed in the production of precast concrete elements. It enhances the strength and structural integrity of precast components, such as beams, columns, and panels. The fibers offer excellent bonding with the concrete matrix, ensuring reliable connections and reducing the risk of cracking during transportation and installation. - Shotcrete Applications:

Loose hooked end steel fiber is an ideal choice for shotcrete applications, such as tunnel linings and slope stabilization. The fibers provide immediate reinforcement to the freshly sprayed concrete, improving its resistance to cracking and preventing the formation of voids. This results in a more stable and durable structure, even in challenging geological conditions.

Enhancing Concrete Performance with Loose Hooked End Steel Fiber

- Structural Reinforcement:

Loose hooked end steel fiber provides effective structural reinforcement for concrete. The fibers create a three-dimensional network within the matrix, distributing stresses and reinforcing the entire structure. This improves the load-bearing capacity, crack resistance, and overall performance of the concrete. - Simplified Construction Process:

Incorporating loose hooked end steel fiber reduces the need for traditional reinforcement methods, such as steel bars or mesh. This simplifies the construction process, saves time, and eliminates the cost associated with installing and positioning conventional reinforcement. It also allows for more efficient concrete placement, reducing labor requirements. - Cost Savings:

The use of loose hooked end steel fiber in concrete structures can lead to significant cost savings. By eliminating or reducing the amount of traditional reinforcement required, construction expenses are reduced. Additionally, the enhanced durability and crack resistance provided by the fibers results in lower maintenance costs and longer service life for the structures.

Conclusion: Strengthen Concrete Structures with Loose Hooked Steel Fiber

When it comes to reinforcing concrete structures, loose hooked end steel fiber is a reliable and efficient solution. Its ability to enhance crack resistance, increase strength, and improve durability makes it a preferred choice in various construction applications. Whether it’s for industrial flooring, precast elements, or shotcrete, loose hooked end steel fiber provides superior reinforcement, ensuring long-lasting and reliable structures. Incorporate loose hooked end steel fiber in your concrete projects to reinforce with confidence and achieve superior performance.