Galvanized steel fiber is a type of fiber that has been coated with a layer of zinc to enhance its corrosion resistance and durability. It has become a popular choice in various industries due to its numerous advantages and advanced technology. In this article, we will explore the benefits and technology of galvanized steel fiber.

Advantages of Galvanized Steel Fiber

Galvanized steel fiber offers several advantages over traditional steel fibers. One of the most significant benefits is its corrosion resistance. The zinc coating provides a protective layer that prevents corrosion and extends the lifespan of the fiber. Additionally, galvanized steel fiber has a higher tensile strength and modulus of elasticity than traditional steel fibers, making it more durable and resistant to fatigue.

Another advantage of galvanized steel fiber is its resistance to high temperatures. The zinc coating acts as a thermal barrier, reducing the thermal conductivity of the fiber and preventing it from overheating. This makes it an ideal choice for applications in high-temperature environments, such as in the automotive and aerospace industries.

Technology of Galvanized Steel Fiber

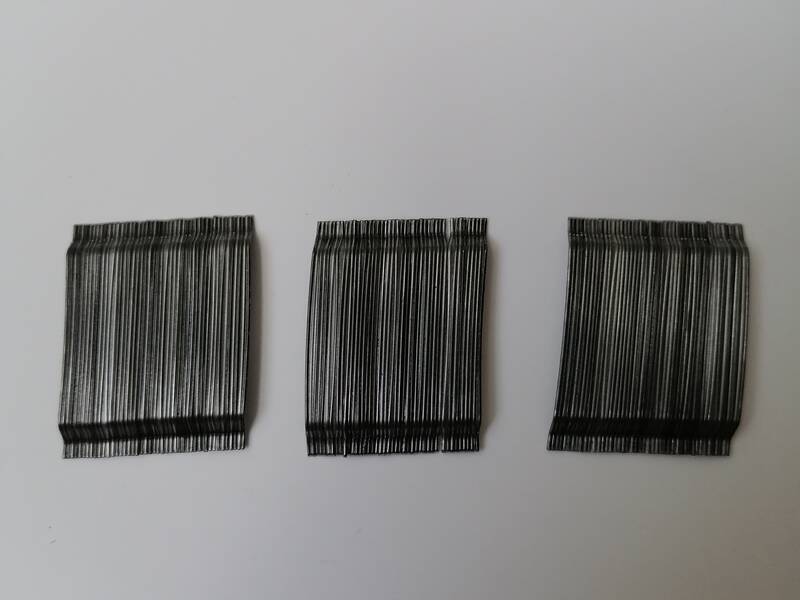

The technology of galvanized steel fiber involves several steps, including surface preparation, zinc coating, and drying. The surface preparation step involves cleaning the steel fiber to remove any impurities and rust, ensuring a smooth and even coating.

The zinc coating process involves applying a layer of zinc to the steel fiber using an electroplating or hot-dip galvanizing method. The zinc layer is then dried in a controlled environment to ensure that it is evenly distributed and free of defects.

The resulting galvanized steel fiber has a uniform zinc coating that provides consistent corrosion resistance and durability. The advanced technology used in the production process ensures that the fiber meets the highest standards of quality and performance.

Applications of Galvanized Steel Fiber

Galvanized steel fiber has a wide range of applications in various industries, including:

- Construction: Galvanized steel fiber is used in reinforced concrete structures, such as bridges, buildings, and roads, to enhance their durability and resistance to corrosion.

- Automotive: Galvanized steel fiber is used in automotive parts, such as brake pads and clutch discs, due to its high heat resistance and durability.

- Aerospace: Galvanized steel fiber is used in aerospace applications, such as aircraft structures and engine components, due to its high strength-to-weight ratio and resistance to corrosion.

- Marine: Galvanized steel fiber is used in marine applications, such as boat hulls and propellers, due to its corrosion resistance and durability in saltwater environments.

Conclusion

Galvanized steel fiber is a highly advanced material that offers numerous advantages and benefits over traditional steel fibers. Its corrosion resistance, durability, and heat resistance make it an ideal choice for various industries. The advanced technology used in its production ensures that it meets the highest standards of quality and performance. As a result, galvanized steel fiber is becoming increasingly popular in various applications, including construction, automotive, aerospace, and marine industries.